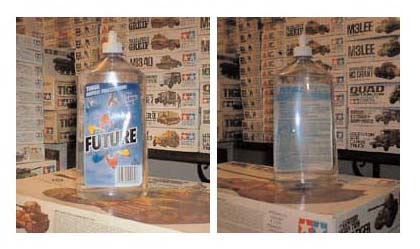

Johnson's "Future" Shine Magic

And it's many Uses

-----------

This is Australia's version of Johnson's "Future" floor polish which is in the photo below. It is sold in most supermarket chains across Australia, it is also known as "Super Shine". The Shine Magic is not exactly clear like the Future, but the effects are the same. Most modelers who use this product, apply it as a clear sealer before and after decaling their models. If too much is sprayed on it can pool easily, so it's best to spray it in light coats. No thinning is needed. Great results have been achieved for matte coats, by mixing the Shine Magic "Future" with Tamiya Flat base. The combination can be mixed anywhere from a 7:1 for extra matte to a 10:1 for a satin matte finish. This product also works very well at coating canopies and clear parts. You can simply dip them in a small receptacle of the Shine Magic and then place them on a lint free cloth to absorb the excess. If you make any mistakes with the Shine Magic, you can simply remove it using ammonia, without causing any harm to the clear plastic. Shine Magic as well as Future can be cleaned from an airbrush with ammonia, denatured alcohol, and isopropyl alcohol. If you have any other tips on using this product or Future, please email them to me and I will be more then happy to add them to this article.

Post By: Taratom

Try airbrushing at 20-25lbs.

psi, shooting at room temperature. My best results have been achieved with a

Paasche H, using the no. 3 tip. I would think any other airbrush with a medium

tip would be fine. The 'white or cloudy effect appears to be an

'etching-chemical' process. I have encountered that too-even with other acrylic

gloss finishes. It's a gremlin that may have to do with excess decal setting

solution application. It is correctable, but an aggravation, nonetheless. I have

also learned to apply Future in thin coats appears pebbly at first but the

effect disappears with the final finish coat], waiting at least 48 hours before

applying decals. The day after decal work, I wash the model with a mild

dishwashing surfactant, such as Dawn or similar agent and, after air drying for

a couple of days or more], another few thin coats of Future are applied to seal

the decals-for final oil-wash and weathering details. I wait at least 48 hours

again] before I airbrush Dullcote, Polyscale or Micro flattening finishes. The

reasoning behind the waiting period in applications, rests on the possibility

that the Future will not cure entirely before a final finish coat is applied,

thereby inducing hairline cracks all over the model. Waiting and making sure the

drying area is at comfortable room temperature seems to avoid this problem. I

once 'shot' a MIG-15 model with, of all things, Pactra flat aluminum thinned

with lacquer thinner. The finish was wonderfully smooth. I applied Future within

a half day, decaled the beast that night, applied Micro scale's original

polyurethane flat finish the next morning, sat the model on a shelf...and some

three weeks later, you guessed it. Fine hairline cracks all over. The paint

solvents, the Future and the final coat solvents; all evaporated at different

rates with dissimilar shrinking of the finish coats as well. Future is a great

product but patience is required in application. I would also recommend that

paint coats be given at least a week to cure prior to airbrushing a finish coat.

This should solve the application of dissimilar paint systems enamels vs.

acrylics] problems too. I may be lucky, but I have never had issues with

airbrushing enamels over acrylics, different acrylic combinations, or acrylics

over enamels.

© Copyright 2000-2001

Model Hangar all rights reserved. This website is owned and maintained by

Anthony Manzoli